Is anyone else having HORRIBLE problems with their Prusa Mk4 or Mk4S first layer quality…

My mk4s developed a problem that Prusa spent 3 months troubleshooting with me where the first layer is being laid down too close, and so filament blobs, then prints fail.

Eventually, they advance replaced my whole printer, and the new one had the exact same problem out of the box…

I managed to find a bug that was raised on github for this exact issue, with 22 other people registering “mee too” for the issue…

I’m just looking for some feedback from the wider community to see if any others have hit this problem?

I had a problem where my Prusa had first layer problems exactly like this but only in a specific area. Two things fixed it. First, increasing the mesh leveling to use the maximum amount of points instead of just 9 or whatever the default is.

The second was discovering the tiny piece of filament that had fallen onto the magnetic heatbet, below the sheet. It dripped from the extruder at some point, and it was black so it was basically invisible. I only found it when I thought to check if anything was making the bed uneven. I didn’t even have to relevel the bed.

at what speed are you printing the first layer and do you use glue?

I had a similar problem (with Creality K1), fixed it by lowering extrusion rate for first layer (in Orca slicer, but there may be such option in the one you’re using too). Changing z-offset would’ve probably helped too.

Preheat the bed for 5 minutes before running leveling.

On mine, I simply increased Z-Offset in the slicer by a fraction of a millimetre.

Can I assume from your response that you have a mk4 or mk4s with this issue then?

Yes

🙏🏻

I can get adequate results with Zoffset or LiveZ +0.04 with smooth sheet and PLA.

PETG is still variable results for same settings, z+0.01 is ok some of the time, others it is still terrible, and still sees filament build up, so if printing real things, it eventually blobs, and has a (bedArea - printArea) chance of then causing a collision.

+0.02 means no bed adhesion, and I can’t actually get a finished first layer.

I’ve never printed with PETG, so I can’t help you there, but I heard it’s a pretty difficult material to get right.

Nah… It’s easy… My previous mk3s+ had hundreds of awwsome PETG hours.

Are you printing PETG?

Yes, but it occurs with both PLA and PETG.

this exact issue

Yours looks nothing like the ones on github. Did you try looking at the printer while it’s failing, can you tell if the filament is not extruding or not sticking?

Thanks…It’s a good point. I’ve updated the post photo, and I’ll add the worse failure mode elsewhere.

On the new photo it’s obviously too close to the bed but consistently so. Looks like the defaults picked by prusa might not be the best. Try what they posted on github, manually change the Z offset in start g-code. Looks like (hopefully temporarily) you’re back to manually tweaking your Z height like a plebeian.

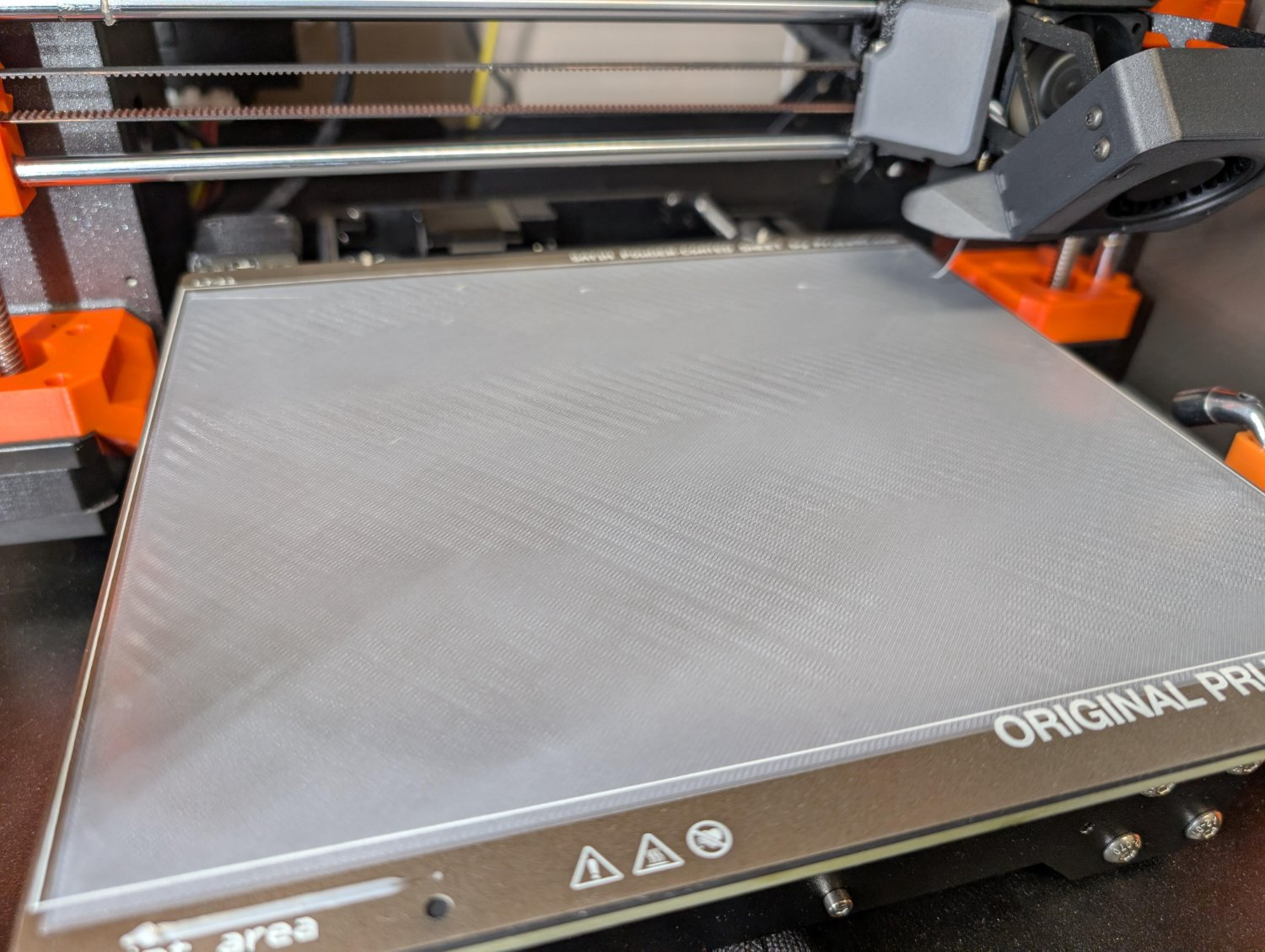

A typical output with PLA.with Zoffset = 0

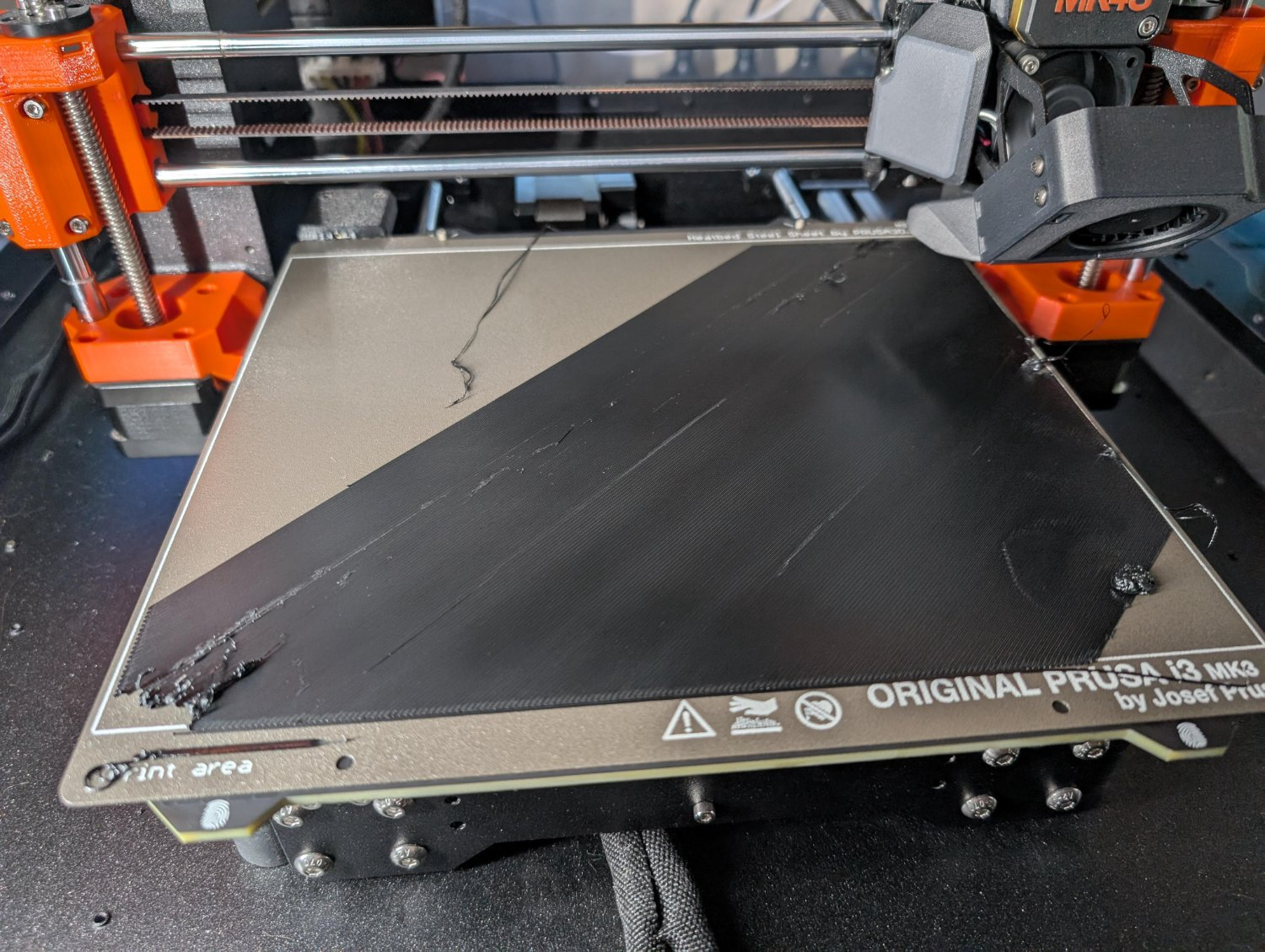

This is one of the worse failure modes I have experienced for this issue. In this instance, the extreme amount of “squish” leads to extreme filament buildup on the nozzle, eventually causing colisions and removing chunks of the FL test.

I’ve only ever had the opposite issue with the nozzle being too far away from the bed due to the bed leveling using a dirty nozzle because the nozzle “cleaning” rutine uses a way too cold nozzle temperature so the plastic is not soft enough to be pushed away and the filament is not retracted so it also oozes because it has been heated for too long. Imo the printer should purge, then retract then clean and then bed level.

Can’t you just change this? Or are Prusa so locked down that they don’t allow control of the printer?

Interesting that people might think this. Prusa was/is THE open source printer company.

Isn’t their entire FW closed and using proprietary boards? AFAIK replacement parts are also only available as STLs? That’s somewhat halfhearted open source IMO.

I believe you’ve confused them with Bambu

No, I believe you hold Prusa to a higher standard than they actually deliver. It’s true their roots are in open source, but these days they are only partially open source and their control board is not open source at all.

It’s true it could be better. They used to be more open source. Like they used to just publish their firmware source as they released it. Now days they hold back the current generation till the next gen is out. They mentioned this was so they could be more competitive with companies that do less R&D and more cloning.

Like even their slicer was just reskinned etc. it’s in peoples rights to reskin an open source slicer but I see why they did it.

Maybe “was” is the better word. Still better than things like Bamboo though.

If you wanted to customise the starting gcode, I’m sure you could.